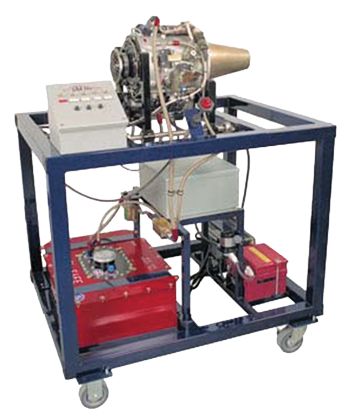

The Model AE-11 Turbine Engine Training System is a functional,scaled down turbine engine ideally suited for training applications.The engine is a small compact free turbine engine manufactured by Honeywell/Allied Signal Inc. Elaborate safety features built in this engine test stand make it one of the safest designs on the market for education and testing roles. It comprises a gas generator and an accessory drive assembly. The gas generator incorporates a centrifugal compressor, an axial flow turbine rotating unit and an ignition and combustion system. The accessory drive assembly incorporates a lubrication pump, a fuel pump, a 50% cut-out switch, a generator and an electric start motor The engine has been modified from its original purposes as a gas turbine engine starter by removing the power recovery turbine and gear reduction unit and replacing with a custom fabricated exhaust nozzle to allow for continuous operation while not under load. The fuel control unit has been modified to allow for control of engine rpm by a Vernier throttle control.

Engine Specifications:

- Thrust: 50 lbs (222N)

- Fuel: Jet A (can also be operated on K-1 Kerosene)

- Exhaust Gas Temp: 1475°F(800°C)

- Mass Flow: 1.6 lb/s (0.7 jg/s)

- Ignition system: Air gap, high voltage capacitordischarge type, hermetically sealed, ignition coil and igniter plug

- Compressor Type: Single stage radial outflow

- Turbine Type: Single stage axial flow

- Engine RPM: 74,000 rpm max

- Engine Mount: Two .75 inch polished steel rods via 4 linear ball bearings, allowing a direct thrust reading to be obtained by a load cell

Instrumentation:

Sensors are provided to measure direct thrust (from a load cell), fuel flow, engine rpm pressure at various stages of the engine and temperature at each stage of the engine. The LabVIEW™ software calculates the thrust from the fuel flow,temperature and pressure readings. The user has access to a wide range of data acquisition, graph plotting and display functions, such as:

- Ambient temp.

- Compressor entry temp.

- Compressor exit temp.

- Compressor entry pressure

- Compressor exit pressure

- Turbine entry temp.

- Turbine exit pressure

- Nozzle exit temp.

- Nozzle exit pressure

- Oil pressure

- Oil inlet temp.

- Oil outlet temp.

- Fuel flow

- Air flow

- Shaft speed

- Thrust

Training Materials:

The Training System is provided with user manual, and extensive educational materials, including a CBT module